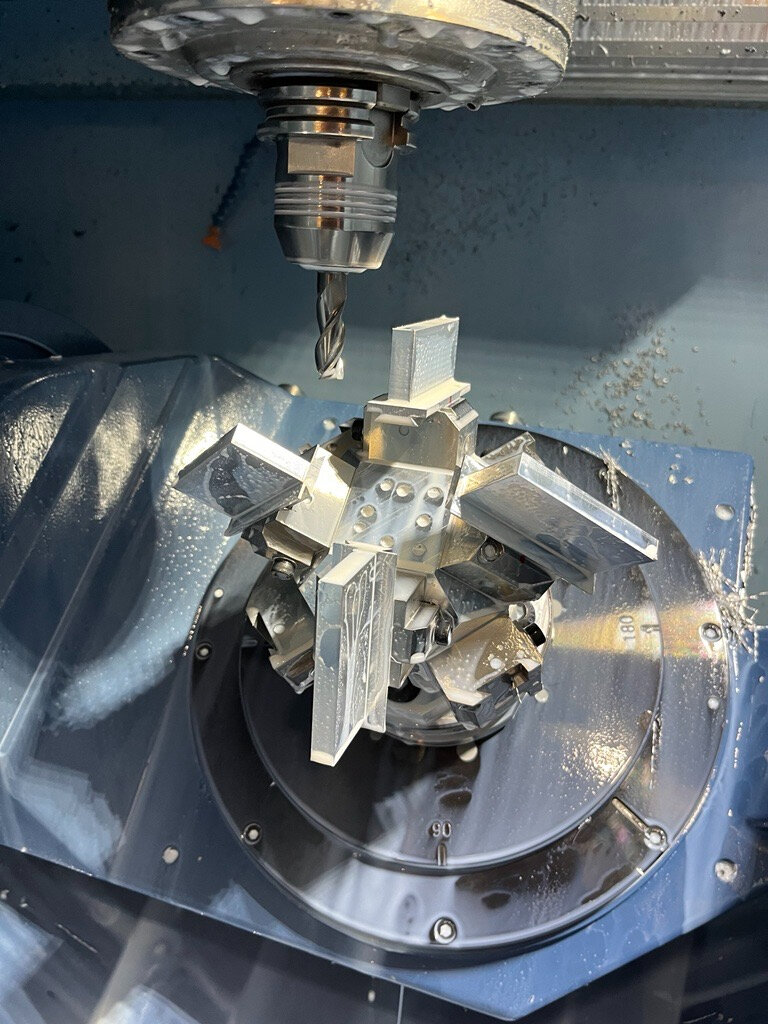

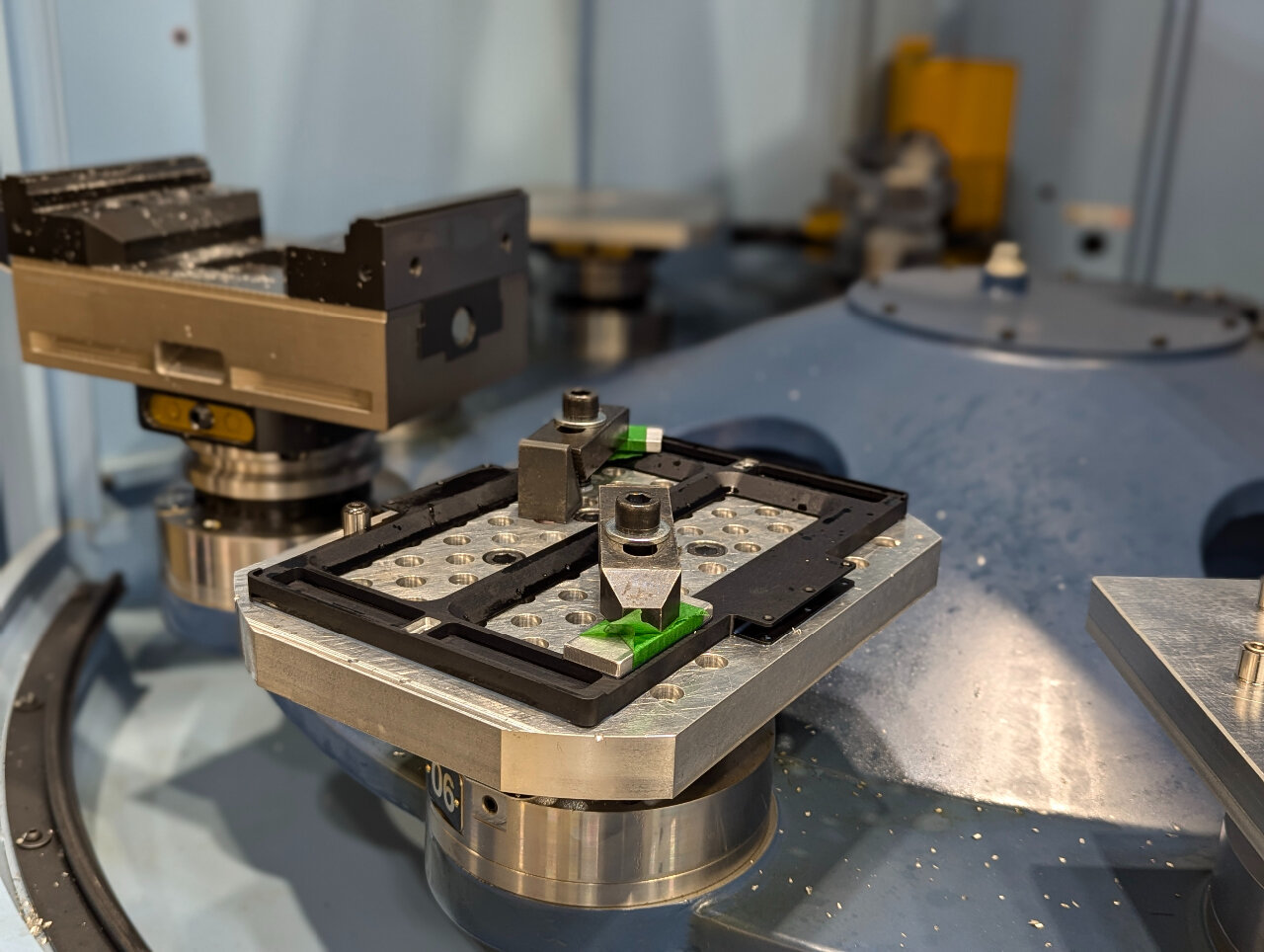

With our manual and CNC milling machines, as well as an advanced laser cutting machine, Ball Service Group’s end-to-end machining services are your comprehensive solution to projects of any size. We're experts in consistently precise, tight-tolerance milling applications ranging from small businesses to high throughput production. We serve customers ranging from healthcare organizations looking to build prototype machines to automotive shops wanting to commission custom parts.

With a mix of both Manual and 3 and 5 Axis CNC machining capabilities, we use our expertise to help customers identify what's the best fit. We consider your budget, needs, and specifications to determine whether to use Manual, CNC, or Laser to best serve your project.

Our quality management system is ISO 9001 certified.

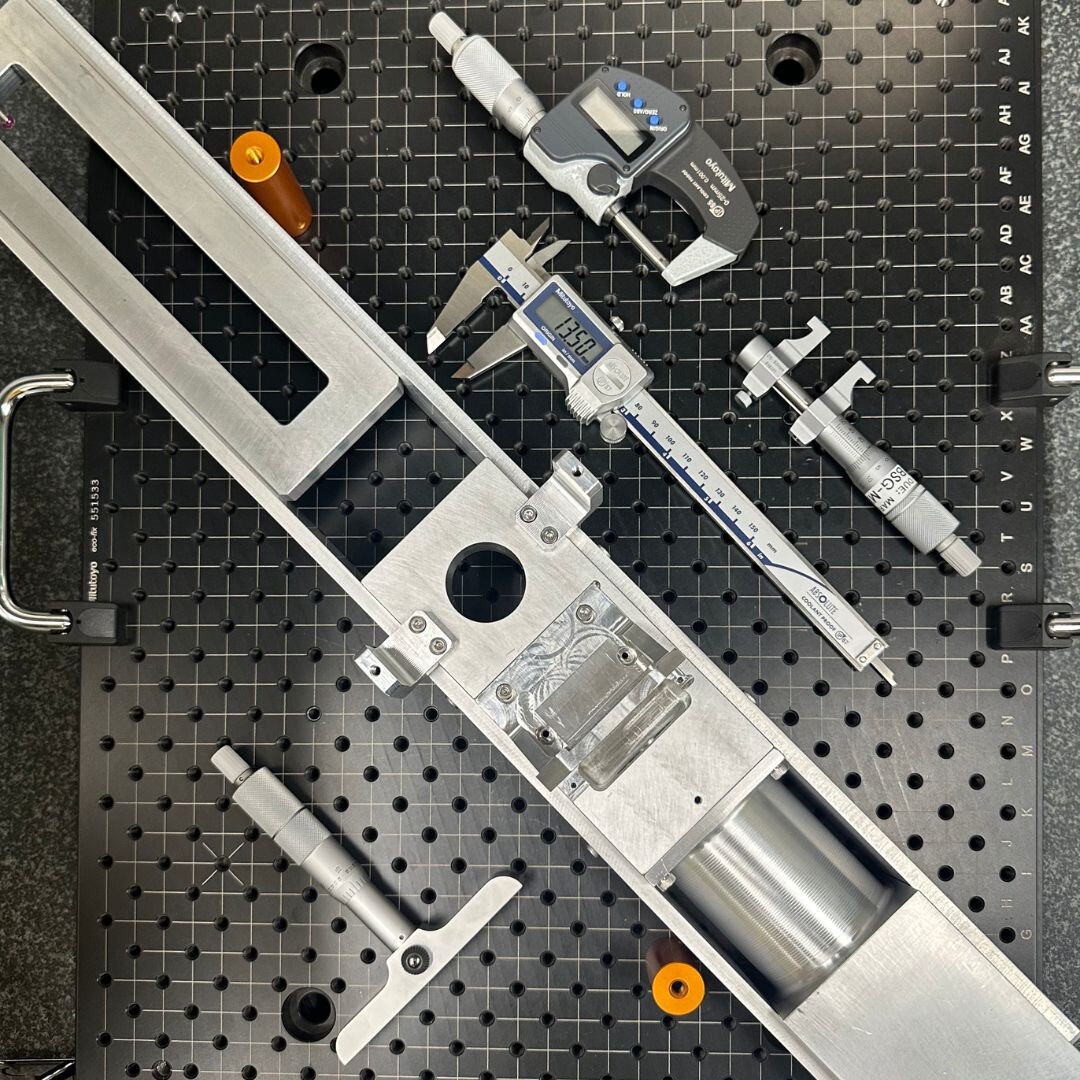

For Quality Inspection

MiSTAR Series 555 CNC CMM

Using metrology tools

Materials:

We are capable of milling a wide range of metals and select plastics including:

Our hybrid fiber laser can cut several metals including

Aluminum

Stainless steel

Various steel alloys

Example Applications:

Automotive Parts Production

Product of Pathology Scanner Components

Medical Device Production

Vehicle & Equipment Prototypes

Prototyping Services:

Reach out to us to ask any questions!

Our team has engineers and technicians who can create professional engineering drawings and CAD models to turn your idea into a manufactured product. Some clients may choose to be very descriptive and detailed, while others might not have specific details sorted out yet. Whatever your preference is, we have professionals who will work with you to meet your needs.

BSG offers both CNC and Manual Milling services. Both Manual and CNC Milling have their respective advantages and disadvantages, depending on the size and type of project. When you contact us to start working on your project, we’ll consider your needs and budget to determine which is right for you.

The Hybrid laser cutting machine is capable of cutting both tubes and sheets, unlike standard laser cutting machines which are typically designed for one or the other. The hybrid laser cutting machine at BSG incorporates state-of-the-art technology, offering enhanced precision, efficiency, and cutting quality.

Please fill in the fields below and click "submit" to contact us.