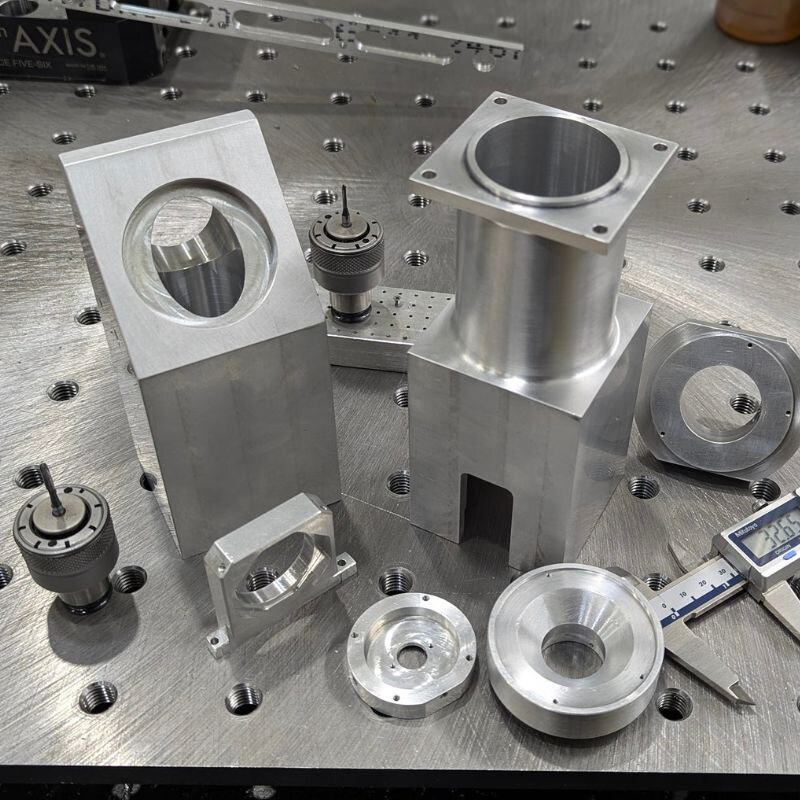

With our manual and CNC milling machines, as well as an advanced laser cutting machine, Ball Service Group’s end-to-end machining services are your comprehensive solution to projects of any size. We're experts in consistently precise, tight-tolerance milling applications ranging from small businesses to high throughput production. We serve customers ranging from healthcare organizations looking to build prototype machines to automotive shops wanting to commission custom parts.

Machining to

tolerances*

Axis capabilities

*Tolerances depend on feature size. We will work with you to provide highly accurate parts where accuracy is required and reduce cost where accuracy is not required.

See more of our Machining services

Agility

We can rapidly respond to design changes and modify existing prototype parts to meet your needs.

Assembly

We reduce time to market for your products with full assembly and modification services. If something doesn’t work, we work with you to address any issues before the parts leave our facility. This shortens development time by removing delays caused by shipping parts back and forth.

Medical Expertise

We service all sorts of industries and customers but are especially knowledgeable in the medical industry. We can source RoHS compliant materials, ensure proper alignment and precision for opto-mechanical components, and meet stringent design requirements.

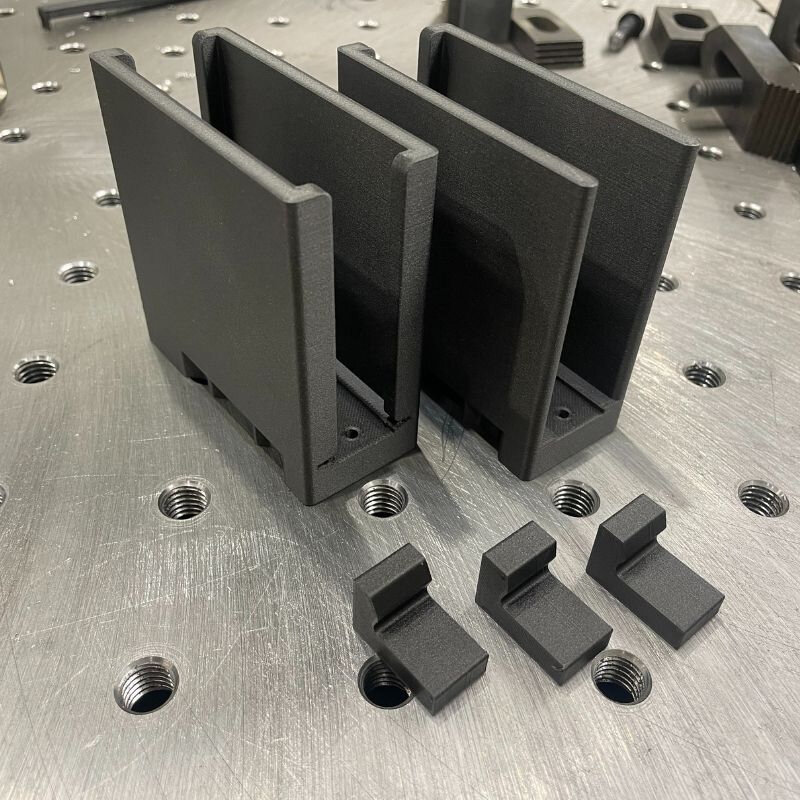

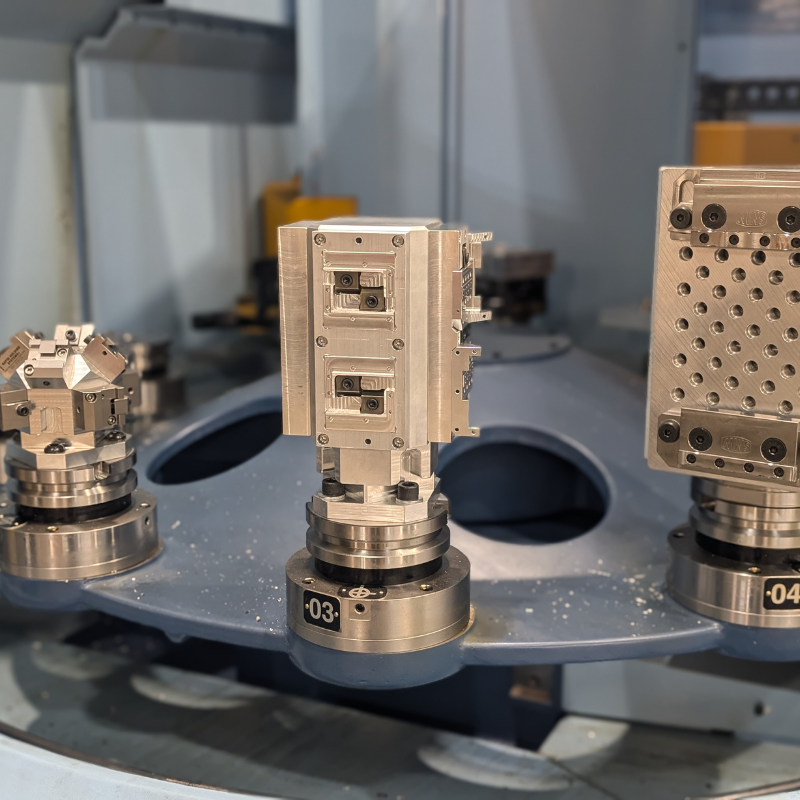

Modular Fixtures

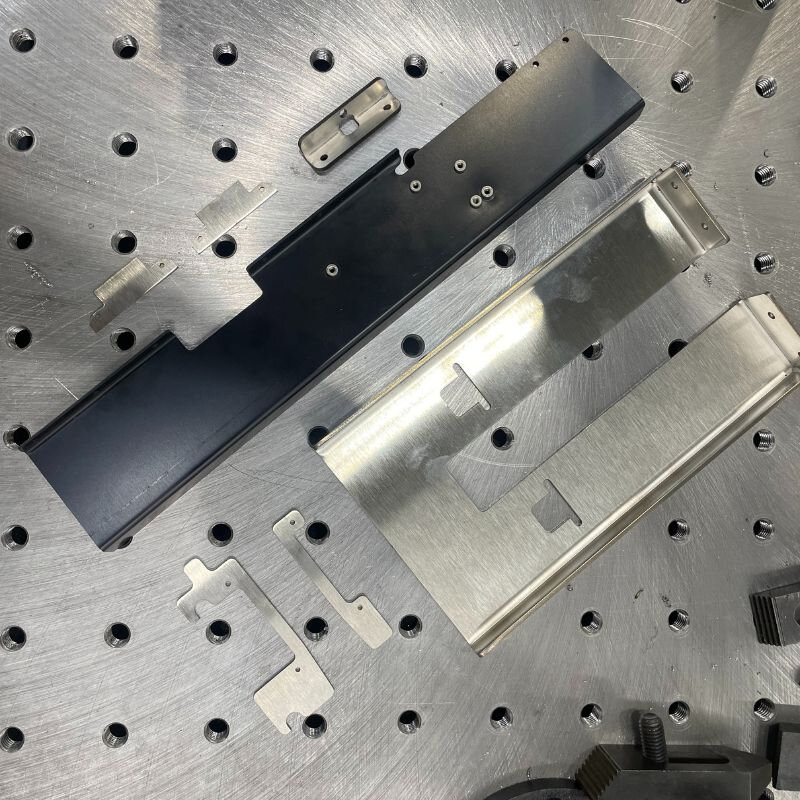

Our highly modular CNC fixtures allow us to fit a wide range of parts in batches depending on part size. Our 5-axis CNC is fully automated including an automatic pallet changer with 10 pallets for lights-out production.

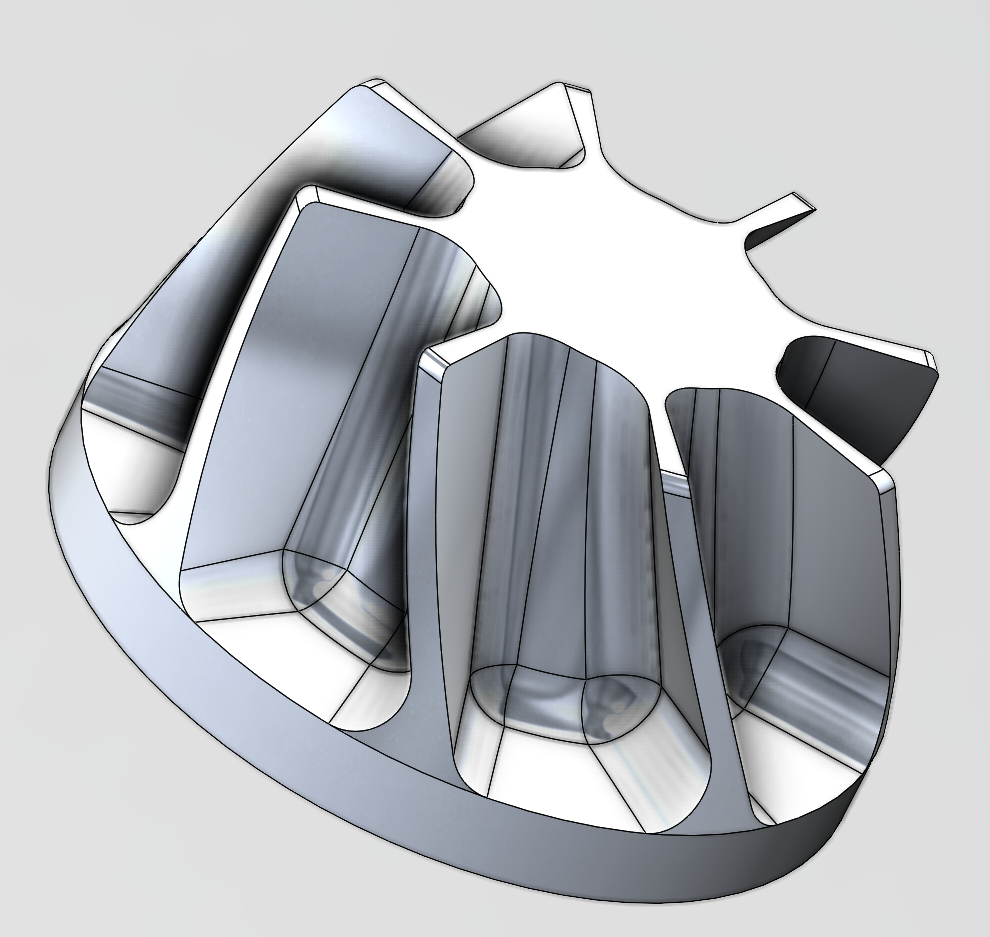

Custom Fixtures

We are also capable of batching, fixturing, and machining complex geometries that would be impossible with traditional milling setups.

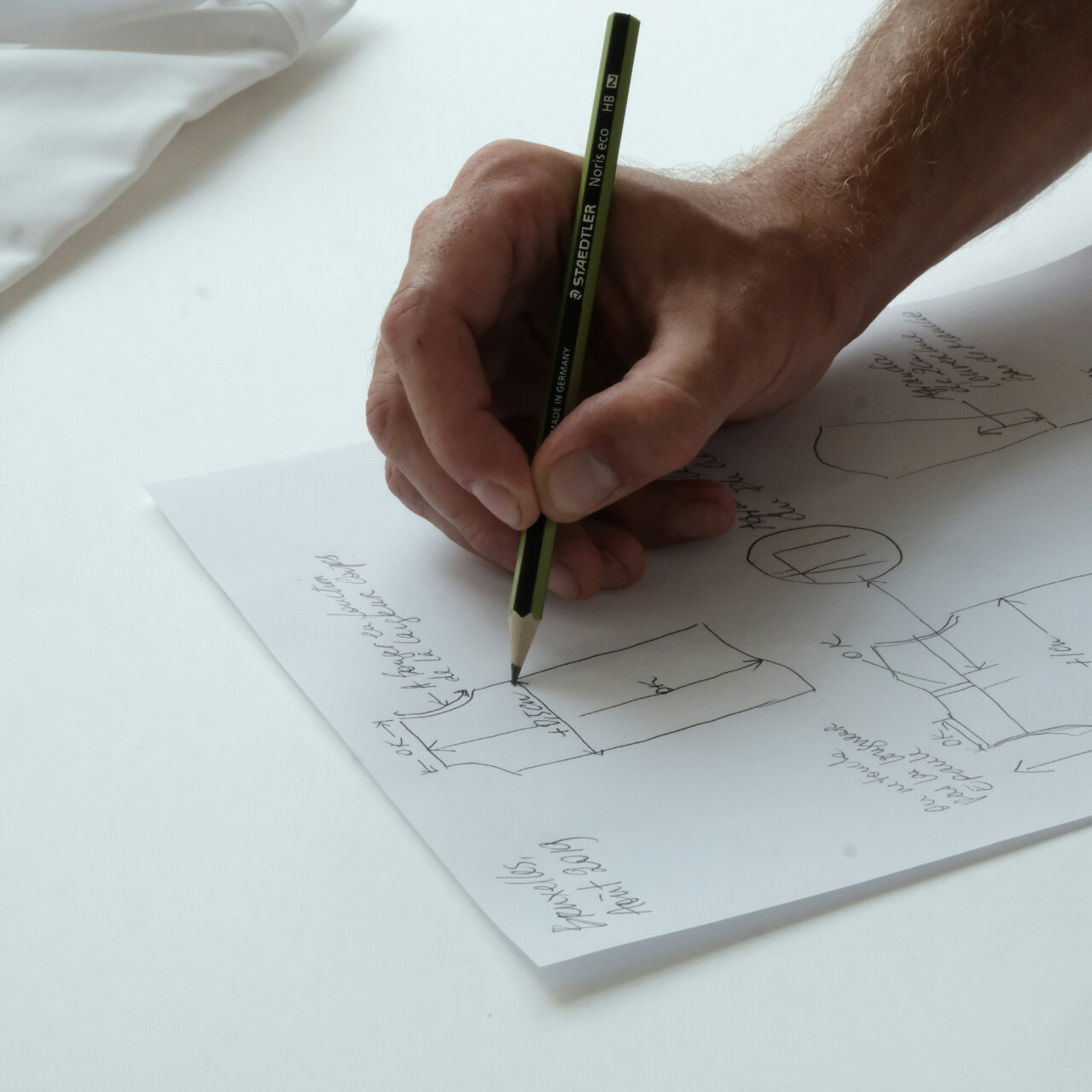

Product Design

Our experienced engineers can help you bring your ideas to life. We offer end-to-end design services ranging from consultations to prototyping to delivering low volume production products.

Design for Manufacturing (DFM)

We can work with your engineers to make your parts more easily manufacturable without reducing quality or functionality.

Engineering Drawings

We can create engineering drawings with full GD&T controls so that your part can be made anywhere in the world, and it will always fit.

We follow the ISO 9001 quality management system. This means we follow routine procedures and have controlled documentation on all relevant processes in our business.

We have a 100% inspection process for prototype parts and production parts are inspected based on a thorough procedure at multiple stages of manufacturing. You can be confident that all our parts conform to our strict quality standards.

We use our MiSTAR Series 555 CNC CMM for components with particularly demanding precision requirements to ensure your parts are conformant down to the micrometer.

Our team has engineers and technicians who can create professional engineering drawings and CAD models to turn your idea into a manufactured product. Some clients may choose to be very descriptive and detailed, while others might not have specific details sorted out yet. Whatever your preference is, we have professionals who will work with you to meet your needs.

Please fill in the fields below and click "submit" to request your quote