August 15th, 2024, Metal Fabrication, Laser Cutting

Metal fabrication is an essential craft that supports various industries, including automotive, construction, and consumer products, producing everything from small precision parts to large structural frameworks. In this article, we will delve into the cutting stage of metal fabrication and explore how laser cutting has brought unprecedented precision, speed, and versatility to the process. Discover the transformative benefits of laser cutting and its wide-ranging applications across several industries, from creating vehicle components to customized fencing and gates.

Metal fabrication is the process of building machines and structures from raw metal materials. It involves various skilled procedures including cutting, bending, and assembling to create metal parts or structures. Key processes in metal fabrication include:

Cutting: The initial step where metal pieces are cut to the required dimensions using tools such as saws, lasers, plasma cutters, or water jets.

Bending: Forming the metal into desired shapes by using press brakes, tube benders, or other tools.

Fitting: Preparing and assembling metal components in a manner that ensures they align correctly before any permanent joining

Welding: The permanent joining of two or more metal parts together by applying heat, pressure, or both, typically causing the metal to melt and fuse.

Assembling: Joining metal pieces together through various methods like welding, riveting, bolting, or using adhesives.

In this article, we’ll specifically cover the cutting stage of metal fabrication and the role laser cutting has played in enhancing metal fabrication.

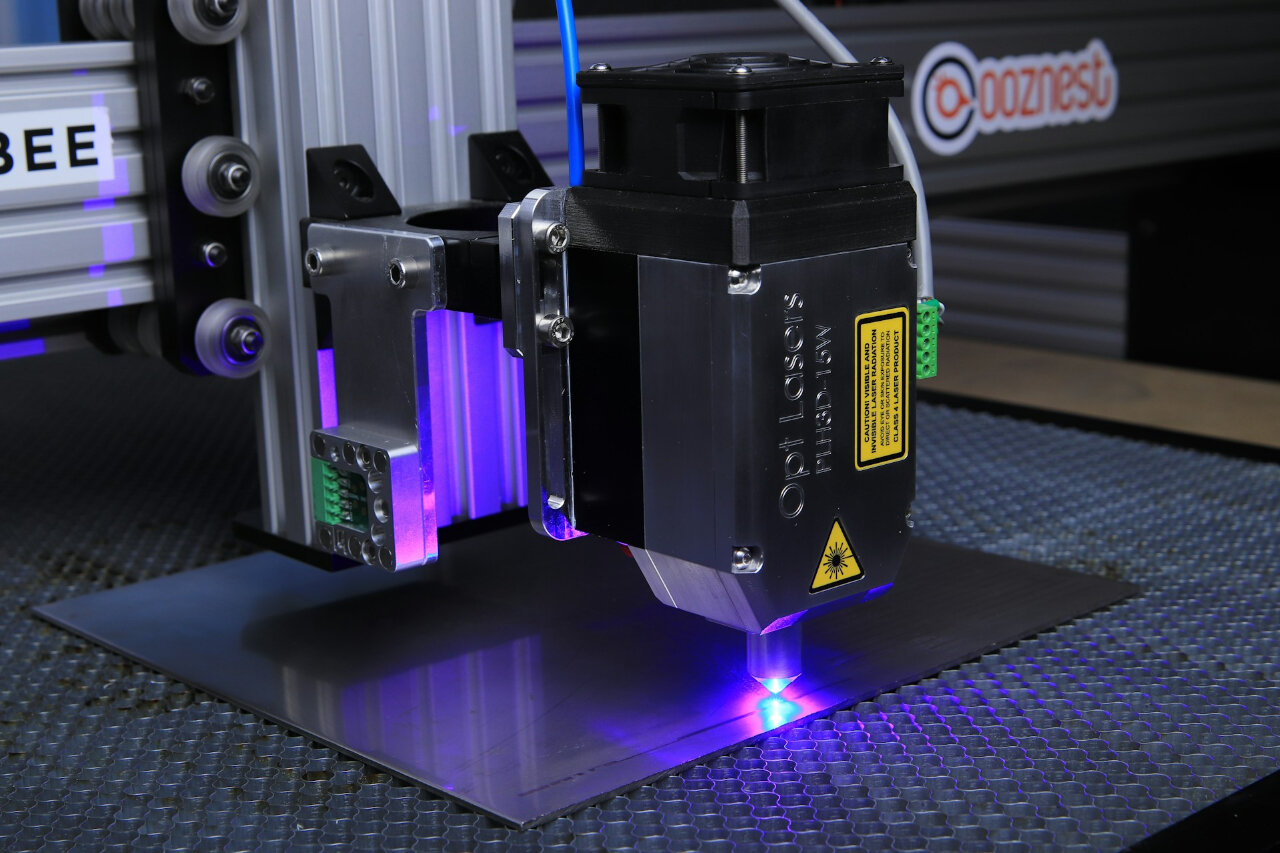

Laser cutting machines are advanced tools used in various industries for cutting materials with high precision. It uses a high-powered laser beam to cut or engrave materials. This laser can be generated using different types of lasers, such as CO2 or fiber lasers. The laser beam is focused to a fine point with high intensity, generating enough heat to melt, burn, or vaporize the material at the point of contact. Laser cutting machines have revolutionized various industries by offering high precision, speed, and versatility.

Let’s dive into some of the industry-wide laser cutting metal fabrication applications.

Metal fabrication takes up a large amount of space in the construction industry, ranging from structural and decorative purposes. Metal fabrication is an essential part of construction, as it helps to create durable and efficient structures and/or components. Construction industries benefit from laser cutting services to get high capacity metal fabrication projects executed quickly and accurately.

Our laser cutting services offer the cutting of components for:

Other laser cutting applications you may see for construction include the cutting of building infrastructure like pipes and ductwork, windows and door frames, gutters and downspouts, and more.

The oil and gas industry demands high-quality equipment and infrastructure that can withstand harsh conditions and ensure safety. Reliable functioning is key, with metal fabrication as the main fortifier that allows the stability of oil & gas components.

Our laser cutting services offer the cutting of components for:

Some laser cutting machines can also cut pipe sections to precise lengths and specifications, in addition to elbows, tees, reducers, and flanges for pipe fittings. This also includes cutting parts for valves that control the flow of oil and gas through pipelines. Storage tanks, processing equipment, subsea components, and safety and control systems for oil and gas pipelines are also manufactured with laser cutting.

On a smaller scale, home renovation projects will often involve metal fabrication, especially in scenarios where the structure of the home is being changed. Like other industries, home renovation needs metal fabrication to maintain the durability and structural integrity of newly constructed spaces. Metal fabrication with laser cutting offers special customization to homeowners, making it versatile for both structural and decorative purposes. Here’s a list of some of the areas where metal fabrication using laser cutting applies:

Laser cutting may also be employed for functional renovations to HVAC systems, cutting ductwork components and fabricating custom plumbing fixtures and fittings.

Ball Service Group houses Ontario’s only Amada 9kW ENSIS 3015 RIe laser, one of the most versatile laser cutting machines available in Ontario. Using the ENSIS fiber laser, the machine has variable beam control to process a expansive range of materials and their thickness. The machine operates with the assist gasses O2 and Nitrogen, maximizing their benefits and expanding the capabilities of the laser cutting machine. Ball Service Group’s Amada laser is capable of producing laser cut materials quickly and efficiently, while also managing projects of large or small capacity.

With the Amada laser cutting machine’s precision and automation, we can help you conquer metal fabrication projects from customized home fencing and gazebos to more industrial applications such as gas compressors for oil and gas, lifting beams for construction, and robot mounting bases for automotive. Trust BSG to bring your project to life. Submit a sketch idea and request a quote today. No drawings available? Our team can draft a sketch for you: Contact us.