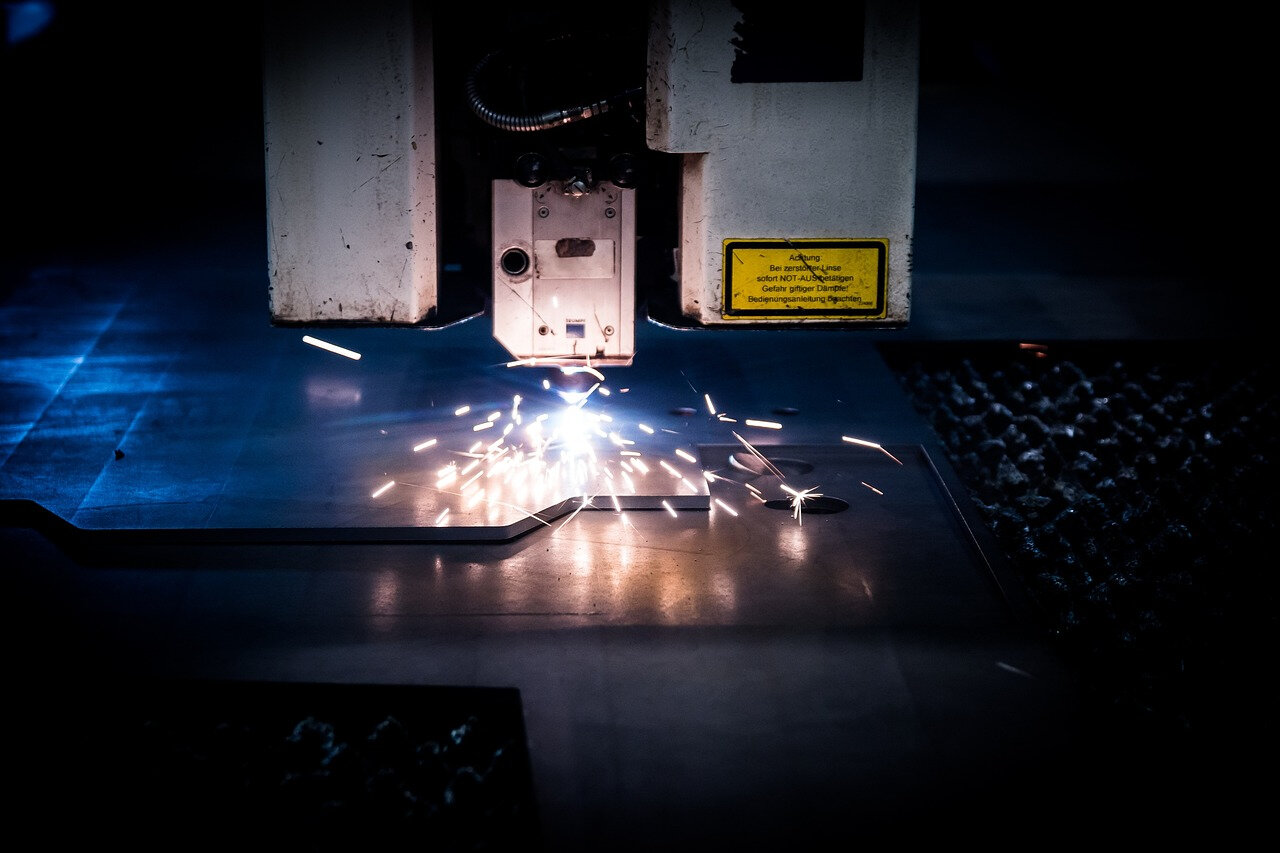

August 13th, 2024, Laser Cutting

Laser cutting is a modern milestone in today’s society, successfully innovating industrial cutting with unprecedented efficiency and precision. Like much of today’s manufacturing methods, the cutting process was originally a long and tedious human-led endeavor that would benefit society in a multitude of ways. Starting at the very beginnings of civilization, industrial cutting has grown substantially throughout centuries of human evolution and experimentation. In this article, we’ll explore the early beginnings of industrial cutting, the changes it faced throughout human history, and the pivotal entry of laser cutting technology.

Early human ancestors were innovative and strategic, creating cutting techniques with whatever resources were at their disposal. Stone, bone and copper were the most commonly used natural resources for making cutting tools. Early humans would repeatedly strike stone (the core) against hard objects to gradually alter its shape. This process would be used to create rudimentary tools such as weapons for hunting and protection. Although effective, the process was predictably inconsistent compared to today’s standards. Nevertheless, the ability to cut and shape materials was critical for survival, prompting early humans to refine their techniques.

The discovery of metallurgy around 4000 BCE, marked a significant turning point. With this, tools, weaponry, and architecture became stronger, sharper, and more durable. Early civilizations such as the Sumerians, Egyptians, and Chinese started working with metals like copper and bronze, which allowed for the creation of more effective cutting tools. Various types of metal became a valuable resource to be purchased and traded, bolstering the economies of these early societies.

The evolution of cutting tools across these early civilizations foreshadowed the pivotal role that these technologies would play in societal advancement. The development of better cutting facilitated improvements in various industries, which in turn supported population growth, and later, urbanization.

In the 1960s, just as the world was increasingly embracing technological advancements, laser technology made its debut. The first laser was made by Theodore H. Maiman in 1960 and paved the way for subsequent development and refinement, eventually birthing laser cutting technology.

The term 'laser' is an acronym for "Light Amplification by the Stimulated Emission of Radiation". The unique properties of laser light – its ability to stay focused over a great distance and to concentrate light energy intensely – made it an efficient and effective tool for a range of applications.

The inauguration of this technology was a revolution in itself. The very first laser cutting machine was used to drill holes in diamond dies. Then, in the 70s, companies began to use lasers to cut titanium for aerospace applications. The laser cutter proved to be a functionally versatile and reliable tool, which quickly found its way into numerous industries.

From humble beginnings, laser cutting technology evolved at a rapid pace. Innovations emerged, one after another, bringing us closer and closer to the efficient and precise laser cutting machines we see today. Earlier models used the CO2 laser, which was ideal for cutting, boring, and engraving. These machines provided a level of accuracy and reliability that was previously unfathomable in the realm of industrial cutting. Laser cutting technology brought many innovations to the cutting process:

Over the years, laser cutting technology has witnessed significant improvements in terms of speed, performance, accuracy, and safety. The 1980s saw the inception of the ‘Flying Optics’ laser cutting machines that drastically improved speed and productivity. In the 2000s, fiber laser technology was introduced, which provided superior speed, quality of cut, and accuracy. It also allowed laser cutting technology to be used without concern of oxidation that could be caused by a CO2 laser. This was a game-changer in the industry, and till this day continues to be a widely used laser cutting technology.

Technological advancements and innovative efforts are continually driven towards making the technology more efficient, accurate, and user-friendly. Cutting-edge advancements include:

The advent of AI is set to revolutionize not just laser cutting, but the manufacturing sector as a whole. The future of laser cutting machines is expected to be more and more AI-driven. The early onset of AI in the current laser cutting climate has helped optimize laser power, speed, and focal position in real-time, significantly increasing overall efficiency. As laser cutting AI continues to develop, it’s expected to continue expanding mechanical capabilities and reducing the amount of human interference required to execute precise laser cutting.

Take your fabrication project to the next level with Ball Service Group, a leader in the laser cutting industry. Our team leverages the power of advanced laser cutting machines to offer you the highest standards of precision and quality.

Whether you need simple or complex parts, our experienced team can manage a wide range of materials and thicknesses with precision, thanks to our state-of-the-art laser cutters. Backed by decades of experience in metal fabrication and a dedication to technological innovation, Ball Service Group is committed to meeting your laser cutting needs. Experience the power and precision of modern laser cutting technology with Ball Service Group today.